Tel: +86-(0)532 6609 8998

| Availability: | |

|---|---|

Dry Bulk Liner, which is also called as container liner, is widely used for 20ft/ 30ft/ 40ft ISO container, suitable for bulk free-flowing granules and powder.

are undoubtedly one of the most economical solutions for fluid bulk cargo. The transportation distance of bulk cargo is usually very long and needs to be transported from one continent to another, so it makes full use of the advantages of containers. The liner will be installed close to the inner wall of the container, it makes full use of the space of the container, which is equivalent to forming another nested “container” in the container.

For food stuff like flour, starch, coarse salt, granulated sugar etc., we supply Food Grade Dry Bulk Liner, to ensure that foods are stored in a dry and clean environment during the transport. When transport commodity with poor flow performance like flour, which is difficult to discharge, a fluidizing system is equipped with the dry bulk liner on the container floor so as to make the discharge efficient.

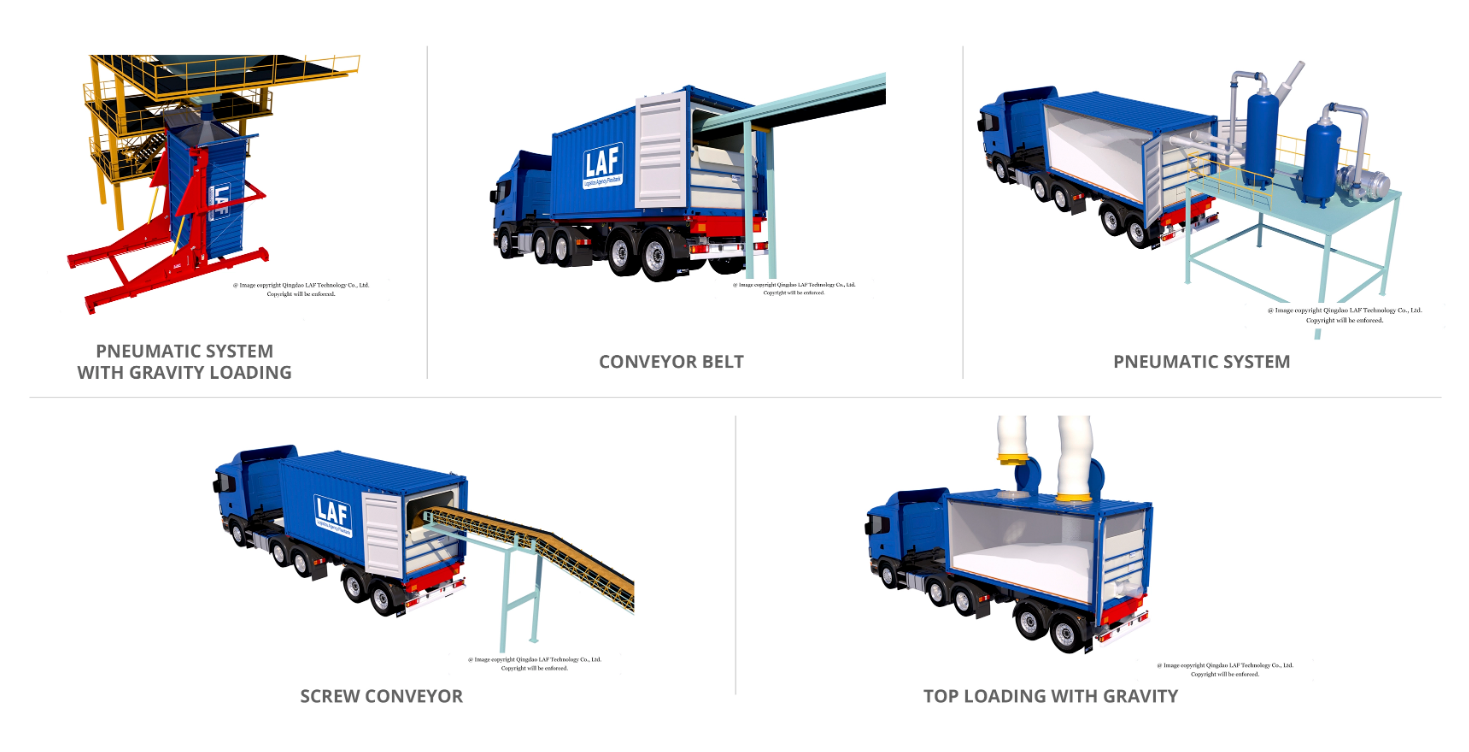

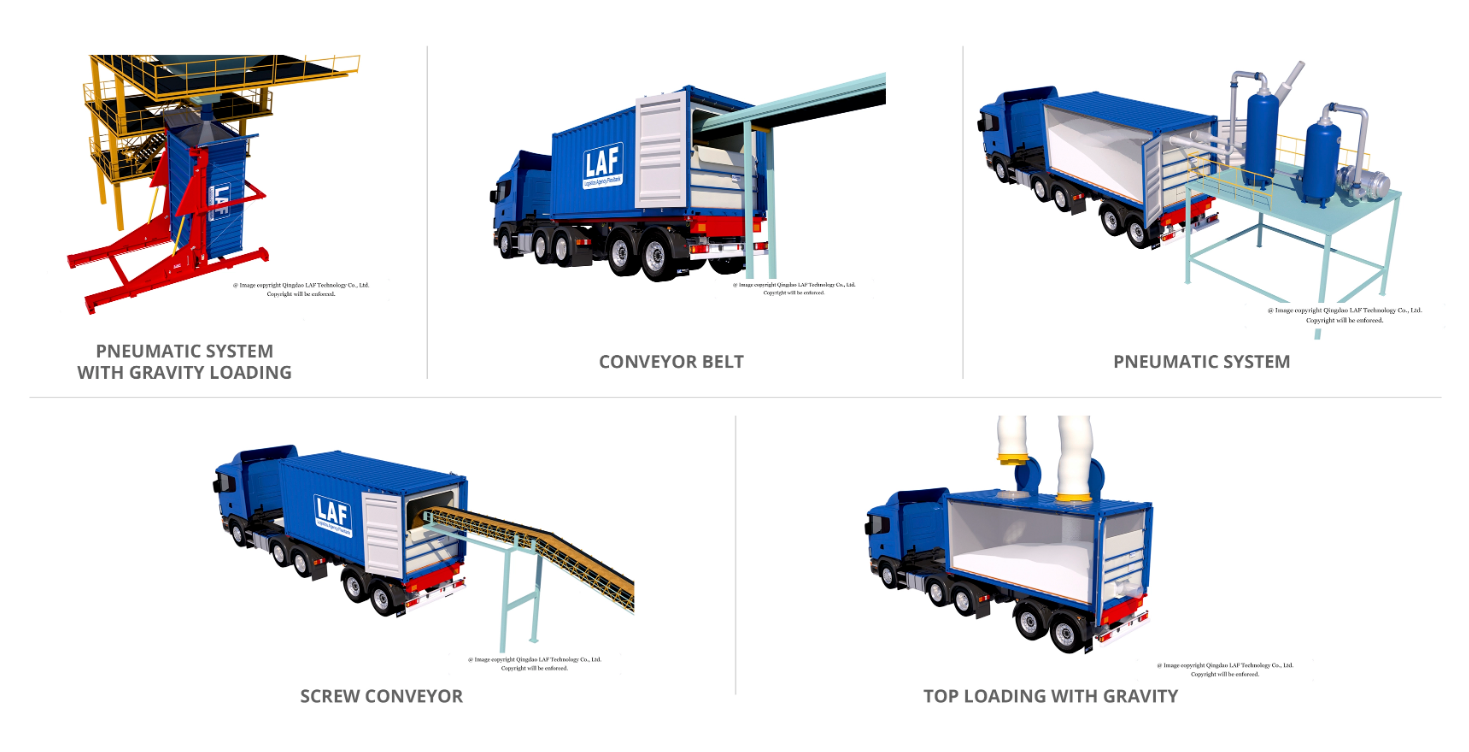

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin,PP resin, PET pellets,PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products.

Flour, Starch, Coarse Salt, Granulated Sugar or similar products.

Barley, Malts, Grains, Peas, Beans, Lentils, Rice, Cocoa Beans, Fish meal or similar agricultural products.

LAF is a worldwide leading manufacturer of economic dry bulk liners, with cutting edge production techniques, offering full-service and technical support covering every aspect in the course of dry bulk commodity shipment.

Comprehensive silo-to-silo dry bulk transport solution is designed to suit specific requirements of each client.

It usually starts with a comprehensive assessment of production, storage and transportation of a factory. With senior experience and expertise in bulk commodity supply chain, and our team at LAF DRY BULK LINER DEPT. helps client to optimize their dry bulk logistics cycle with tailor-made dry bulk liners, assistance in development of dry bulk handling equipment for load and unload containers with dry bulk commodities.

● Maximally utilize container space

● Save packaging cost

● Easy to set up

● Can be tailor-made to various containers, e.g. 20’GP, 40’GP, 35’ containers etc.

● Can be tailor-made to match different filling and discharging equipment

● Loading/Unloading operation with 45 minutes by 2 operators

● Protect product from damage of moisture and/or contamination

• 12 years focusing on Dry Bulk Liner and PP fabrics manufacturing and marketing.

• Annual Production Capacity: 100,000+ container liners per year.

• Excellent and experienced R&D team with expertise for both ODM and OEM support.

Any sizes, any specifications, any logos are acceptable.

We also supply sample order service.

LAF combina flexitanque, dry bulk liner con transporte de contenedores, y transforma un contenedor estándar en un contenedor que puede transportar líquidos, polvos o gránulos no peligrosos, que se pueden utilizar en el transporte por carretera, ferrocarril y mar. En comparación con el patrón regular de embalaje y transporte, esta nueva solución puede mejorar significativamente la eficiencia logística de productos a granel, reducir los costos logísticos y mejorar el ROI por carga de manera notable.

Dry Bulk Liner, which is also called as container liner, is widely used for 20ft/ 30ft/ 40ft ISO container, suitable for bulk free-flowing granules and powder.

are undoubtedly one of the most economical solutions for fluid bulk cargo. The transportation distance of bulk cargo is usually very long and needs to be transported from one continent to another, so it makes full use of the advantages of containers. The liner will be installed close to the inner wall of the container, it makes full use of the space of the container, which is equivalent to forming another nested “container” in the container.

For food stuff like flour, starch, coarse salt, granulated sugar etc., we supply Food Grade Dry Bulk Liner, to ensure that foods are stored in a dry and clean environment during the transport. When transport commodity with poor flow performance like flour, which is difficult to discharge, a fluidizing system is equipped with the dry bulk liner on the container floor so as to make the discharge efficient.

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin,PP resin, PET pellets,PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products.

Flour, Starch, Coarse Salt, Granulated Sugar or similar products.

Barley, Malts, Grains, Peas, Beans, Lentils, Rice, Cocoa Beans, Fish meal or similar agricultural products.

LAF is a worldwide leading manufacturer of economic dry bulk liners, with cutting edge production techniques, offering full-service and technical support covering every aspect in the course of dry bulk commodity shipment.

Comprehensive silo-to-silo dry bulk transport solution is designed to suit specific requirements of each client.

It usually starts with a comprehensive assessment of production, storage and transportation of a factory. With senior experience and expertise in bulk commodity supply chain, and our team at LAF DRY BULK LINER DEPT. helps client to optimize their dry bulk logistics cycle with tailor-made dry bulk liners, assistance in development of dry bulk handling equipment for load and unload containers with dry bulk commodities.

● Maximally utilize container space

● Save packaging cost

● Easy to set up

● Can be tailor-made to various containers, e.g. 20’GP, 40’GP, 35’ containers etc.

● Can be tailor-made to match different filling and discharging equipment

● Loading/Unloading operation with 45 minutes by 2 operators

● Protect product from damage of moisture and/or contamination

• 12 years focusing on Dry Bulk Liner and PP fabrics manufacturing and marketing.

• Annual Production Capacity: 100,000+ container liners per year.

• Excellent and experienced R&D team with expertise for both ODM and OEM support.

Any sizes, any specifications, any logos are acceptable.

We also supply sample order service.

LAF combina flexitanque, dry bulk liner con transporte de contenedores, y transforma un contenedor estándar en un contenedor que puede transportar líquidos, polvos o gránulos no peligrosos, que se pueden utilizar en el transporte por carretera, ferrocarril y mar. En comparación con el patrón regular de embalaje y transporte, esta nueva solución puede mejorar significativamente la eficiencia logística de productos a granel, reducir los costos logísticos y mejorar el ROI por carga de manera notable.

+86-(0)532 6609 8998

+86-(0)532 6609 8998