Tel: +86-(0)532 6609 8998

| Availability: | |

|---|---|

Dry Bulk Liner, which is also called as container liner, is widely used for 20ft/ 30ft/ 40ft ISO container, suitable for bulk free-flowing granules and powder.

Dry Bulk Liner have been the best solution for bulk non-hazardous free flowing pellets, granules, and powder,

compared with traditional jumbo bags or even small PP woven bags, it makes containerized transportation

of bulk solid materials efficient, and cost-effective.

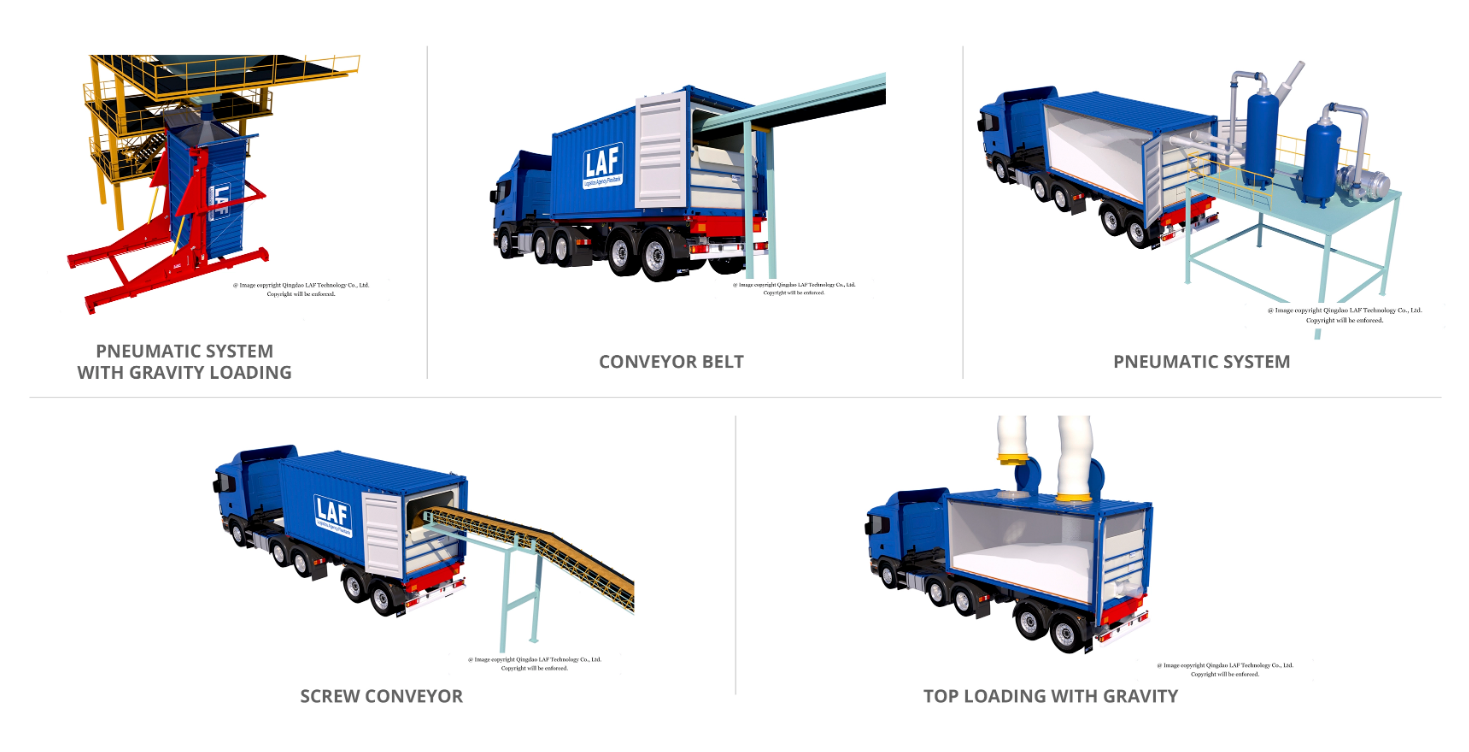

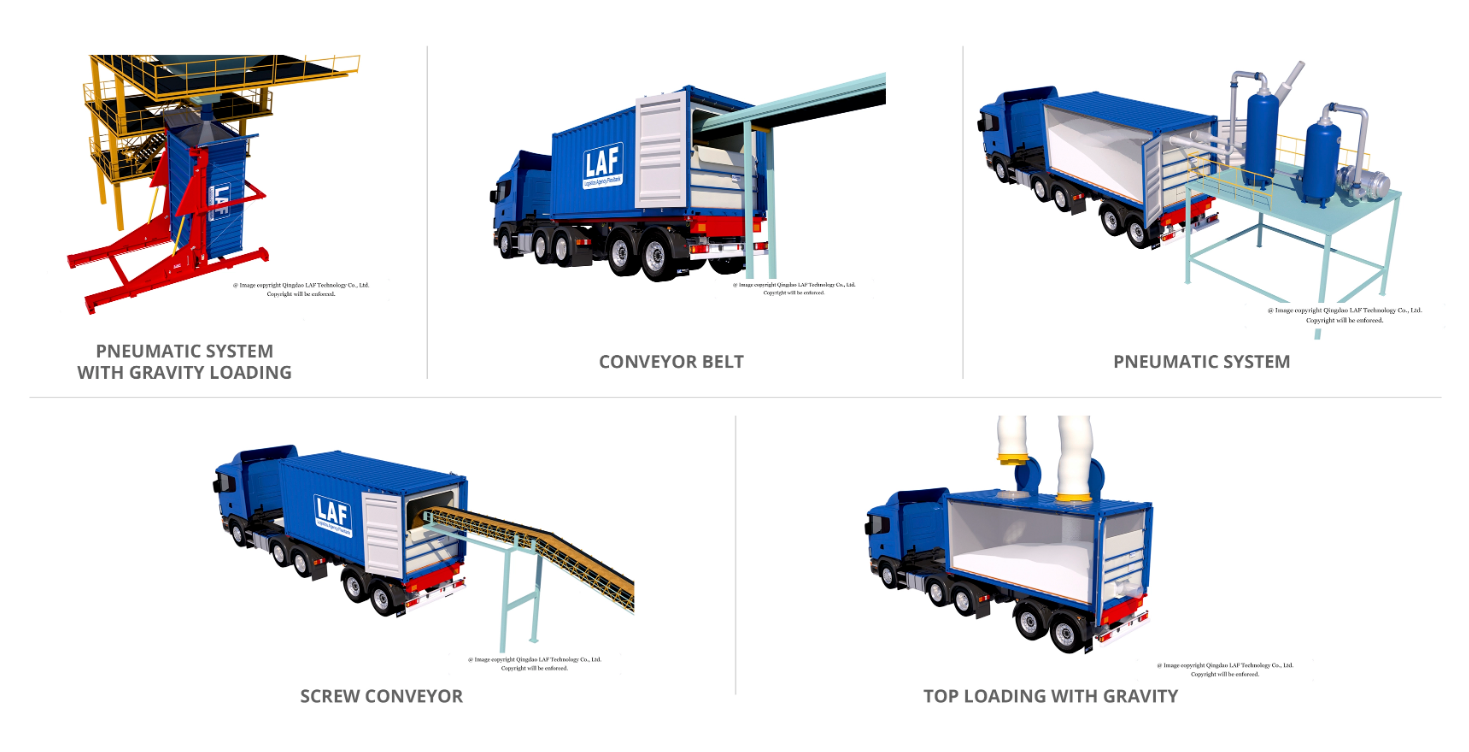

LAF offer Dry Bulk Liners with PE, PP, HDPE, Aluminum materials, and can also design the liner according to container type, physical and chemical properties of cargo, and loading and unloading equipment.

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin,PP resin, PET pellets,PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products

Dry bulk liner is a new type of packaging method that is placed in a 20-foot or 40-foot container and can be used for large tonnage shipments of granular and powdered goods. LAF Technology combines dry bulk liner and containerized transportation to achieve dry bulk containerized transportation, subvert the traditional powder and granular cargo logistics supply chain, and improve the overall efficiency of dry bulk cargo flow and supply chain operation.

● Major advantage of using container liners is that they are very easy to install and require up to 1 or 2 people to complete the installation process without investing too much time or effort.

● In addition, it only takes about 1 hour to fill the goods at place of departure or unload the goods at the destination.

● Compared with the traditional bags, it completely realizes the door-to-door transportation method: eliminating the links of traditional labor filling, moving to the warehouse, packing into the container, and unloading the container to the storage warehouse, thereby it improved efficiency and saved logistics costs.

● In addition to the reduction of logistics links, it can secure the integrity of the goods and reduce cargo losses.

● Besides, because of its excellent sealing and easy disassembly function, compared with bare loading in containers, the cargo residue will be much reduced after unloading from liner bag.

● As a package, it can protect the goods inside. Some dry bulk food commodities have strict sanitary conditions. In this case, the dry bulk container liner bag is used firstly because the liner bag itself can be a food-grade hygiene standard, the second is that it can effectively avoid the invasion of external environmental pollutants during transportation. In addition, it can play a role in moisture-proof.

● For some goods that are easy to pollute containers, such as carbon black, the use of dry bulk container liners can prevent pollution of the container walls and cross-contamination with previously loaded goods, thereby reducing cleaning costs and improving the turnover rate of containers.

Dry Bulk Liner, which is also called as container liner, is widely used for 20ft/ 30ft/ 40ft ISO container, suitable for bulk free-flowing granules and powder.

Dry Bulk Liner have been the best solution for bulk non-hazardous free flowing pellets, granules, and powder,

compared with traditional jumbo bags or even small PP woven bags, it makes containerized transportation

of bulk solid materials efficient, and cost-effective.

LAF offer Dry Bulk Liners with PE, PP, HDPE, Aluminum materials, and can also design the liner according to container type, physical and chemical properties of cargo, and loading and unloading equipment.

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin,PP resin, PET pellets,PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products

Dry bulk liner is a new type of packaging method that is placed in a 20-foot or 40-foot container and can be used for large tonnage shipments of granular and powdered goods. LAF Technology combines dry bulk liner and containerized transportation to achieve dry bulk containerized transportation, subvert the traditional powder and granular cargo logistics supply chain, and improve the overall efficiency of dry bulk cargo flow and supply chain operation.

● Major advantage of using container liners is that they are very easy to install and require up to 1 or 2 people to complete the installation process without investing too much time or effort.

● In addition, it only takes about 1 hour to fill the goods at place of departure or unload the goods at the destination.

● Compared with the traditional bags, it completely realizes the door-to-door transportation method: eliminating the links of traditional labor filling, moving to the warehouse, packing into the container, and unloading the container to the storage warehouse, thereby it improved efficiency and saved logistics costs.

● In addition to the reduction of logistics links, it can secure the integrity of the goods and reduce cargo losses.

● Besides, because of its excellent sealing and easy disassembly function, compared with bare loading in containers, the cargo residue will be much reduced after unloading from liner bag.

● As a package, it can protect the goods inside. Some dry bulk food commodities have strict sanitary conditions. In this case, the dry bulk container liner bag is used firstly because the liner bag itself can be a food-grade hygiene standard, the second is that it can effectively avoid the invasion of external environmental pollutants during transportation. In addition, it can play a role in moisture-proof.

● For some goods that are easy to pollute containers, such as carbon black, the use of dry bulk container liners can prevent pollution of the container walls and cross-contamination with previously loaded goods, thereby reducing cleaning costs and improving the turnover rate of containers.

+86-(0)532 6609 8998

+86-(0)532 6609 8998