Tel: +86-(0)532 6609 8998

| Availability: | |

|---|---|

Dry Bulk Liner, also called as container liner, is the most cost-effective solution for dry cargo transportation and temporary storage. The liner forms a protective barrier between the product and the container interior, minimizes the risks of product quality loss and prevents cargo contamination.

For food stuff like flour, starch, coarse salt, granulated sugar etc., we supply Food Grade Dry Bulk Liner, to ensure that foods are stored in a dry and clean environment during the transport. When transport commodity with poor flow performance like flour, which is difficult to discharge, a fluidizing system is equipped with the dry bulk liner on the container floor so as to make the discharge efficient.

LAF offer Dry Bulk Liners with PE, PP, HDPE, Aluminum materials, and can also design the liner according to container type, physical and chemical properties of cargo, and loading and unloading equipment.

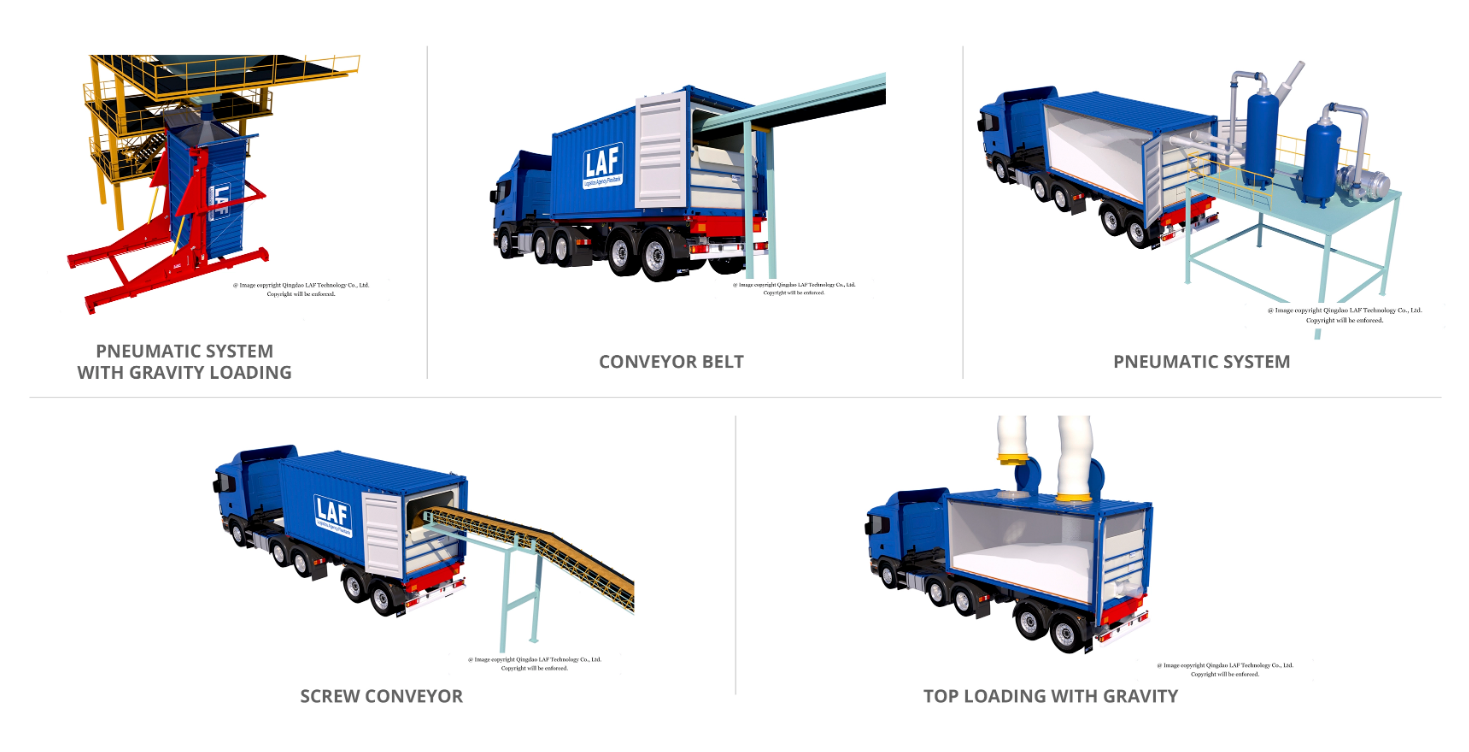

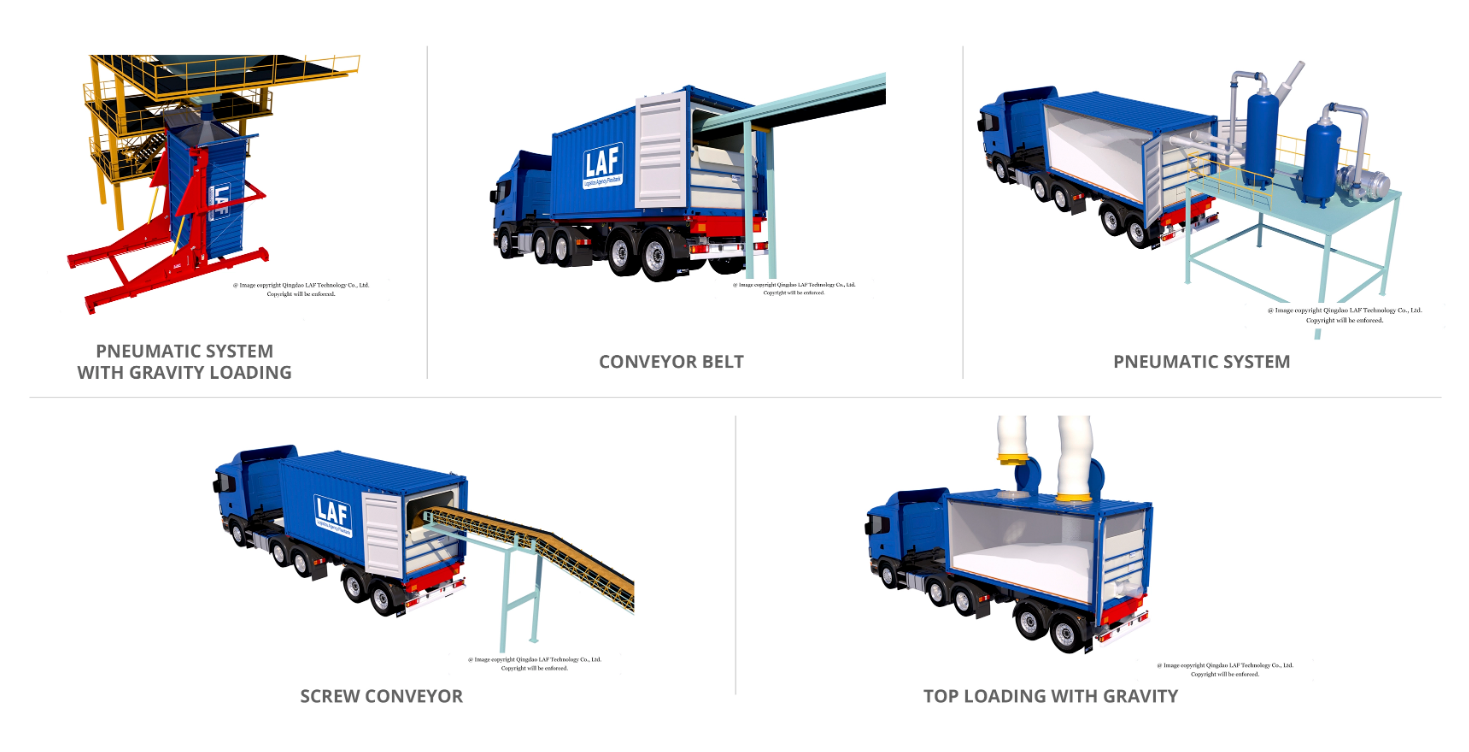

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin,PP resin, PET pellets,PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products.

Flour, Starch, Coarse Salt, Granulated Sugar or similar products.

Barley, Malts, Grains, Peas, Beans, Lentils, Rice, Cocoa Beans, Fish meal or similar agricultural products.

LAF is a worldwide leading manufacturer of economic dry bulk liners, with cutting edge production techniques, offering full-service and technical support covering every aspect in the course of dry bulk commodity shipment.

Comprehensive silo-to-silo dry bulk transport solution is designed to suit specific requirements of each client.

It usually starts with a comprehensive assessment of production, storage and transportation of a factory. With senior experience and expertise in bulk commodity supply chain, and our team at LAF DRY BULK LINER DEPT. helps client to optimize their dry bulk logistics cycle with tailor-made dry bulk liners, assistance in development of dry bulk handling equipment for load and unload containers with dry bulk commodities.

● Major advantage of using container liners is that they are very easy to install and require up to 1 or 2 people to complete the installation process without investing too much time or effort.

● In addition, it only takes about 1 hour to fill the goods at place of departure or unload the goods at the destination.

● Compared with the traditional bags, it completely realizes the door-to-door transportation method: eliminating the links of traditional labor filling, moving to the warehouse, packing into the container, and unloading the container to the storage warehouse, thereby it improved efficiency and saved logistics costs.

● In addition to the reduction of logistics links, it can secure the integrity of the goods and reduce cargo losses.

● Besides, because of its excellent sealing and easy disassembly function, compared with bare loading in containers, the cargo residue will be much reduced after unloading from liner bag.

● As a package, it can protect the goods inside. Some dry bulk food commodities have strict sanitary conditions. In this case, the dry bulk container liner bag is used firstly because the liner bag itself can be a food-grade hygiene standard, the second is that it can effectively avoid the invasion of external environmental pollutants during transportation. In addition, it can play a role in moisture-proof.

● For some goods that are easy to pollute containers, such as carbon black, the use of dry bulk container liners can prevent pollution of the container walls and cross-contamination with previously loaded goods, thereby reducing cleaning costs and improving the turnover rate of containers.

LAF is committed to replacing various "bulk and groceries" transportation modes with a "containerized" transportation mode, replacing manual handling with mechanized loading and unloading, and is committed to improving enterprise logistics efficiency and reducing comprehensive logistics costs. Hope to carry out extensive cooperation with all walks of life to promote the improvement and development of the logistics efficiency of bulk fluid cargo (non-hazardous liquid food, chemicals, grain, powder, granules, etc.).

Dry Bulk Liner, also called as container liner, is the most cost-effective solution for dry cargo transportation and temporary storage. The liner forms a protective barrier between the product and the container interior, minimizes the risks of product quality loss and prevents cargo contamination.

For food stuff like flour, starch, coarse salt, granulated sugar etc., we supply Food Grade Dry Bulk Liner, to ensure that foods are stored in a dry and clean environment during the transport. When transport commodity with poor flow performance like flour, which is difficult to discharge, a fluidizing system is equipped with the dry bulk liner on the container floor so as to make the discharge efficient.

LAF offer Dry Bulk Liners with PE, PP, HDPE, Aluminum materials, and can also design the liner according to container type, physical and chemical properties of cargo, and loading and unloading equipment.

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin,PP resin, PET pellets,PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products.

Flour, Starch, Coarse Salt, Granulated Sugar or similar products.

Barley, Malts, Grains, Peas, Beans, Lentils, Rice, Cocoa Beans, Fish meal or similar agricultural products.

LAF is a worldwide leading manufacturer of economic dry bulk liners, with cutting edge production techniques, offering full-service and technical support covering every aspect in the course of dry bulk commodity shipment.

Comprehensive silo-to-silo dry bulk transport solution is designed to suit specific requirements of each client.

It usually starts with a comprehensive assessment of production, storage and transportation of a factory. With senior experience and expertise in bulk commodity supply chain, and our team at LAF DRY BULK LINER DEPT. helps client to optimize their dry bulk logistics cycle with tailor-made dry bulk liners, assistance in development of dry bulk handling equipment for load and unload containers with dry bulk commodities.

● Major advantage of using container liners is that they are very easy to install and require up to 1 or 2 people to complete the installation process without investing too much time or effort.

● In addition, it only takes about 1 hour to fill the goods at place of departure or unload the goods at the destination.

● Compared with the traditional bags, it completely realizes the door-to-door transportation method: eliminating the links of traditional labor filling, moving to the warehouse, packing into the container, and unloading the container to the storage warehouse, thereby it improved efficiency and saved logistics costs.

● In addition to the reduction of logistics links, it can secure the integrity of the goods and reduce cargo losses.

● Besides, because of its excellent sealing and easy disassembly function, compared with bare loading in containers, the cargo residue will be much reduced after unloading from liner bag.

● As a package, it can protect the goods inside. Some dry bulk food commodities have strict sanitary conditions. In this case, the dry bulk container liner bag is used firstly because the liner bag itself can be a food-grade hygiene standard, the second is that it can effectively avoid the invasion of external environmental pollutants during transportation. In addition, it can play a role in moisture-proof.

● For some goods that are easy to pollute containers, such as carbon black, the use of dry bulk container liners can prevent pollution of the container walls and cross-contamination with previously loaded goods, thereby reducing cleaning costs and improving the turnover rate of containers.

LAF is committed to replacing various "bulk and groceries" transportation modes with a "containerized" transportation mode, replacing manual handling with mechanized loading and unloading, and is committed to improving enterprise logistics efficiency and reducing comprehensive logistics costs. Hope to carry out extensive cooperation with all walks of life to promote the improvement and development of the logistics efficiency of bulk fluid cargo (non-hazardous liquid food, chemicals, grain, powder, granules, etc.).

+86-(0)532 6609 8998

+86-(0)532 6609 8998