Tel: +86-(0)532 6609 8998

| Availability: | |

|---|---|

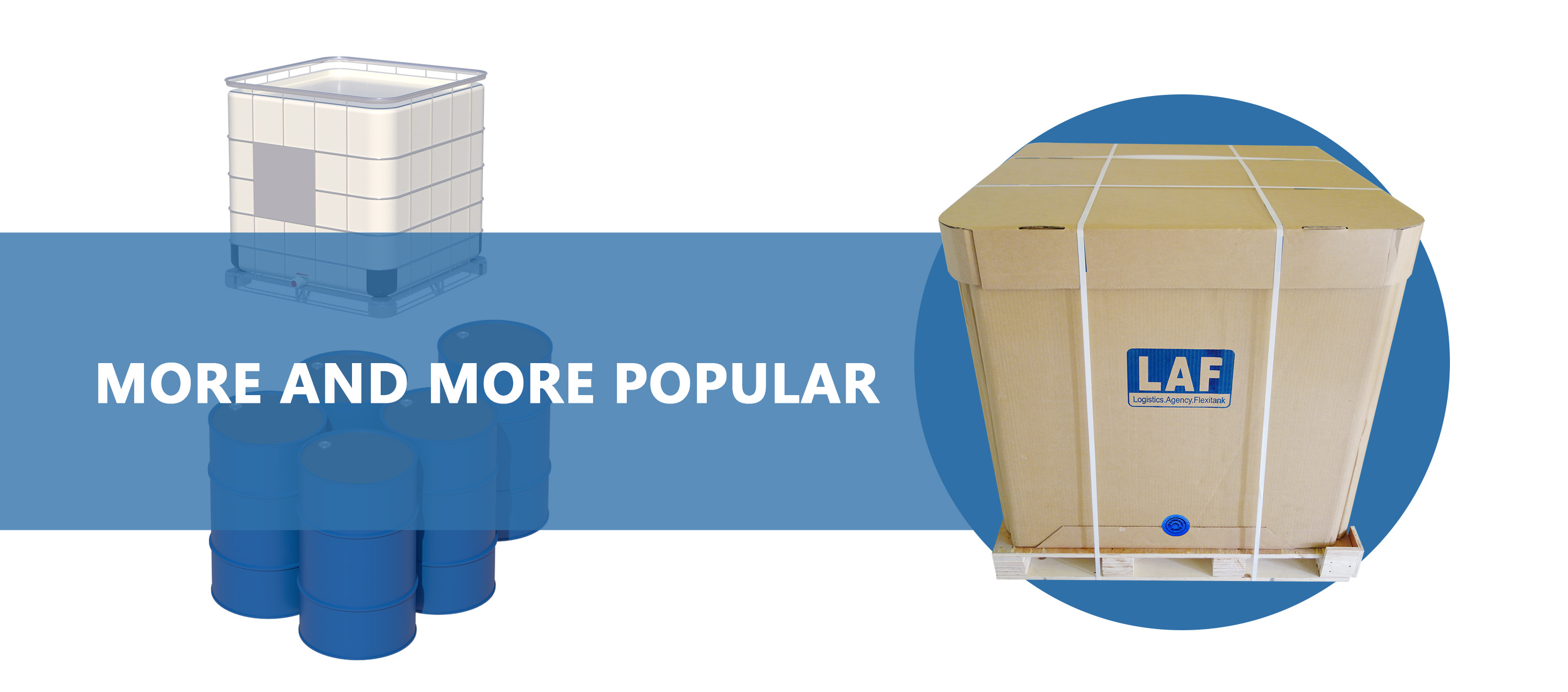

The Single Trip Paper IBC with Liquid Bag represents a paradigm shift in bulk liquid handling, combining eco-conscious design with operational efficiency for modern logistics. As a premier collapsible bulk container, this innovative solution integrates a robust outer structure of high-strength cardboard with a food-grade inner multi-layer PE liner, creating a synergistic system that outperforms traditional drums, returnable IBCs, and bottle-in-cage alternatives across key performance metrics.

Designed specifically for one-way transportation cycles, this disposable IBC solution eliminates the logistical complexities and reverse shipping costs associated with reusable containers. Its lightweight yet durable construction ensures reliable protection for bulk liquids while minimizing carbon footprint—a critical advantage in today’s sustainability-driven supply chains. Whether for short-haul distribution or international shipping, this paper-based IBC delivers a compelling value proposition centered on cost optimization and environmental responsibility.

| Collapsible Paper IBC Technical Specification | |

| Capacity | 1000 |

| Loading / Unloading Type | Top Load Bottom Discharge |

| Components | Box, Top Lid, Cassette (including Liner Bag) |

| Dimension | 1100x1100x1000 mm |

| Weight | 48kg (±1kg) |

| Box Thickness | 40 mm |

| Static Stacking | 3 tiers |

| Dynamic Stacking | 2 tiers |

| Pallet Dimension | 1120x1120 cm |

Capacity: 1000L, equivalent to five 200L drums, reducing the number of shipments.

Outer Shell: High-strength corrugated paper provides excellent compression resistance and stacking stability.

Inner Bag: Food-grade PE material with a leak-proof design, ensuring safe liquid transport.

Stacking: Dynamic stacking up to 2 layers; static stacking up to 3 layers, optimizing storage efficiency.

Ideal for transporting fruit juices, edible oils, syrups, and dairy products, the container’s food-grade certification (including Kosher and Halal compliance) ensures product integrity from origin to destination. Its contamination-resistant design makes it suitable for both organic and conventional liquid food products.

The ultra-clean manufacturing environment meets cGMP standards, making this IBC suitable for transporting cosmetic bases, pharmaceutical intermediates, and personal care ingredients. The inert liner material prevents product adulteration while maintaining strict hygiene standards.

For non-hazardous chemicals, lubricants, and industrial additives, the container provides secure containment with excellent chemical resistance properties. Its robust construction minimizes the risk of spillage during transit, enhancing workplace safety.

From liquid fertilizers to crop protection solutions, the container’s durable design withstands the rigors of agricultural logistics. Its collapsible nature reduces storage requirements on farms and at distribution centers during off-season periods.

Is the Single Trip Paper IBC suitable for international shipping?

Yes, the container is engineered to meet international transportation standards, including COA certification for maritime transport. Its structural integrity ensures performance across various climate conditions and transportation modes.

How does the environmental impact compare to returnable IBCs?

While returnable IBCs have multi-trip advantages, studies show single trip paper IBCs generate less overall emissions for shipments exceeding certain distance thresholds due to eliminated return transportation. The renewable resource base further reduces environmental footprint.

What temperature ranges can the container accommodate?

The PE liner maintains stability across a broad temperature spectrum, suitable for most ambient and moderately heated liquid applications. For extreme temperature requirements, specialized liners are available upon request.

The Single Trip Paper IBC with Liquid Bag represents a paradigm shift in bulk liquid handling, combining eco-conscious design with operational efficiency for modern logistics. As a premier collapsible bulk container, this innovative solution integrates a robust outer structure of high-strength cardboard with a food-grade inner multi-layer PE liner, creating a synergistic system that outperforms traditional drums, returnable IBCs, and bottle-in-cage alternatives across key performance metrics.

Designed specifically for one-way transportation cycles, this disposable IBC solution eliminates the logistical complexities and reverse shipping costs associated with reusable containers. Its lightweight yet durable construction ensures reliable protection for bulk liquids while minimizing carbon footprint—a critical advantage in today’s sustainability-driven supply chains. Whether for short-haul distribution or international shipping, this paper-based IBC delivers a compelling value proposition centered on cost optimization and environmental responsibility.

| Collapsible Paper IBC Technical Specification | |

| Capacity | 1000 |

| Loading / Unloading Type | Top Load Bottom Discharge |

| Components | Box, Top Lid, Cassette (including Liner Bag) |

| Dimension | 1100x1100x1000 mm |

| Weight | 48kg (±1kg) |

| Box Thickness | 40 mm |

| Static Stacking | 3 tiers |

| Dynamic Stacking | 2 tiers |

| Pallet Dimension | 1120x1120 cm |

Capacity: 1000L, equivalent to five 200L drums, reducing the number of shipments.

Outer Shell: High-strength corrugated paper provides excellent compression resistance and stacking stability.

Inner Bag: Food-grade PE material with a leak-proof design, ensuring safe liquid transport.

Stacking: Dynamic stacking up to 2 layers; static stacking up to 3 layers, optimizing storage efficiency.

Ideal for transporting fruit juices, edible oils, syrups, and dairy products, the container’s food-grade certification (including Kosher and Halal compliance) ensures product integrity from origin to destination. Its contamination-resistant design makes it suitable for both organic and conventional liquid food products.

The ultra-clean manufacturing environment meets cGMP standards, making this IBC suitable for transporting cosmetic bases, pharmaceutical intermediates, and personal care ingredients. The inert liner material prevents product adulteration while maintaining strict hygiene standards.

For non-hazardous chemicals, lubricants, and industrial additives, the container provides secure containment with excellent chemical resistance properties. Its robust construction minimizes the risk of spillage during transit, enhancing workplace safety.

From liquid fertilizers to crop protection solutions, the container’s durable design withstands the rigors of agricultural logistics. Its collapsible nature reduces storage requirements on farms and at distribution centers during off-season periods.

Is the Single Trip Paper IBC suitable for international shipping?

Yes, the container is engineered to meet international transportation standards, including COA certification for maritime transport. Its structural integrity ensures performance across various climate conditions and transportation modes.

How does the environmental impact compare to returnable IBCs?

While returnable IBCs have multi-trip advantages, studies show single trip paper IBCs generate less overall emissions for shipments exceeding certain distance thresholds due to eliminated return transportation. The renewable resource base further reduces environmental footprint.

What temperature ranges can the container accommodate?

The PE liner maintains stability across a broad temperature spectrum, suitable for most ambient and moderately heated liquid applications. For extreme temperature requirements, specialized liners are available upon request.

+86-(0)532 6609 8998

+86-(0)532 6609 8998