Tel: +86-(0)532 6609 8998

| Availability: | |

|---|---|

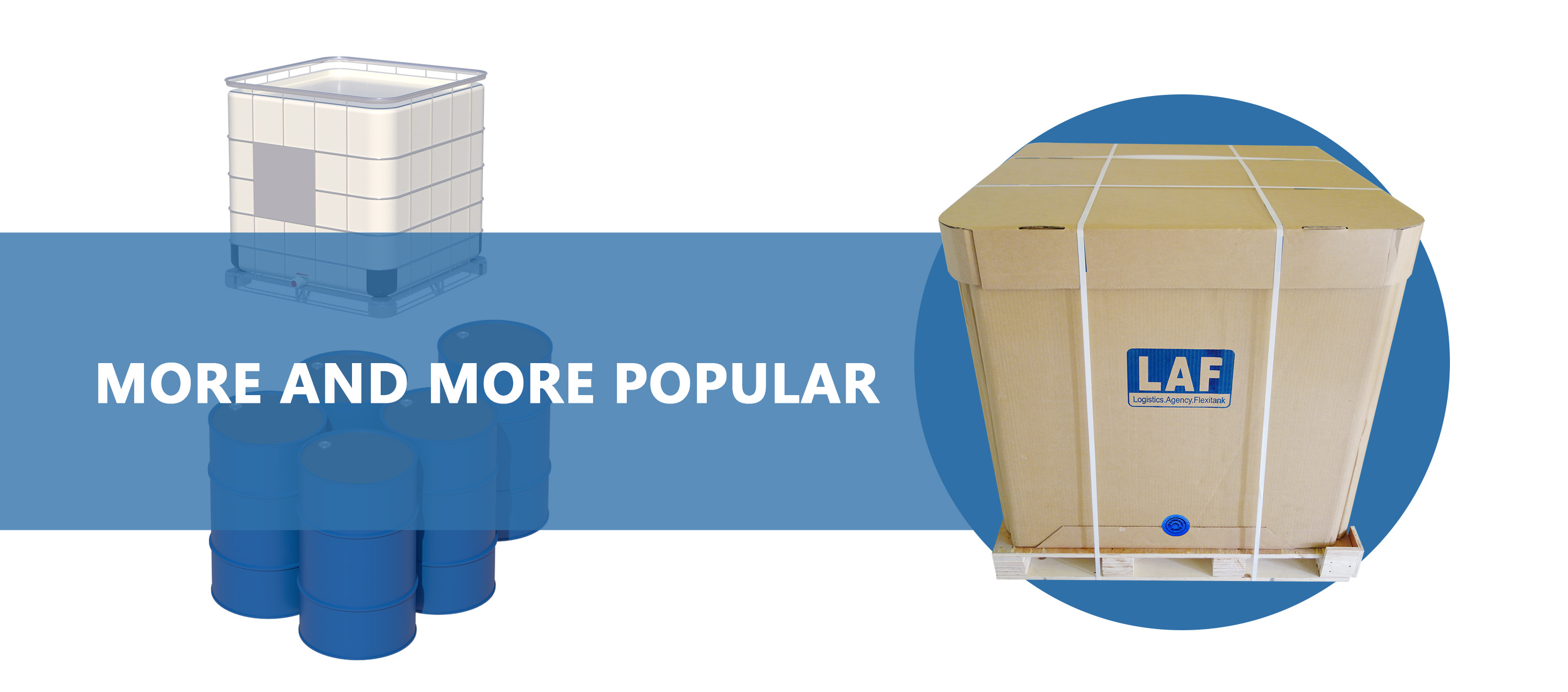

The Economic Paper IBC for Base Oil is a cost-effective packaging solution engineered for the safe transport of industrial lubricants and base oils. With a 1,000-liter capacity and corrugated cardboard outer shell (burst strength 200 psi), it offers 50% cost savings over steel drums by reducing material and logistics expenses . Its FDA-approved PE liners (chemically resistant to mineral and synthetic base oils) ensure compatibility with a wide range of lubricants, while the lightweight design (35kg empty weight) lowers shipping costs by reducing fuel consumption during transport .

Collapsible Design: When empty, the IBC collapses to 20% of its full volume, reducing storage space by 80% compared to rigid IBCs and lowering warehouse costs. This design also eliminates return shipping expenses associated with reusable steel containers .

Chemical Resistance: The inner PE liner (140μm thickness) is formulated to resist swelling and degradation from base oils, withstanding 6 months of continuous contact without leakage or material breakdown. It is compatible with Group I, II, III, and IV base oils, as well as common additives like viscosity index improvers .

Stackable Strength: Reinforced with vertical cardboard ribs, the IBC supports 5-ton static loads when stacked (up to 3 units high), making it suitable for efficient warehouse storage and transport in standard trucks (24 units per 20-foot container) .

Eco-Friendly: The outer cardboard shell is made from 80% post-consumer recycled materials and is fully curbside recyclable. The PE liner is incinerable with minimal toxic emissions, reducing the environmental impact by 40% compared to plastic IBCs .

Lubricant Production:

Delivers bulk base oils to manufacturers of motor oils, hydraulic fluids, and industrial greases, supporting continuous production lines with reliable bulk supply.

Supports bulk supply to automotive service centers, machinery maintenance facilities, and industrial plants requiring regular lubricant replenishment.

Metalworking:

Transports cutting fluids, coolants, and metalworking oils to machining shops and manufacturing facilities, where consistent oil quality ensures optimal tool performance and workpiece finish.

Construction:

Delivers asphalt binders, concrete admixtures, and construction lubricants to job sites, with the durable design withstands rough handling during offloading.

Q: Is it suitable for hazardous liquids?

A: No, it is certified for non-hazardous industrial liquids only. For hazardous materials, we recommend our specialized chemical-resistant IBCs with UN certification.

Q: What is the shelf life?

A: When stored in dry environments (relative humidity <60%) and temperatures between 5°C and 35°C, the IBC maintains integrity for up to 12 months from the production date.

Q: How is it disposed of?

A: The cardboard outer shell is curbside recyclable in most regions. The PE liner can be incinerated in industrial facilities or recycled through plastic recycling programs, with clear disposal instructions printed on the exterior for easy handling.

The Economic Paper IBC for Base Oil is a cost-effective packaging solution engineered for the safe transport of industrial lubricants and base oils. With a 1,000-liter capacity and corrugated cardboard outer shell (burst strength 200 psi), it offers 50% cost savings over steel drums by reducing material and logistics expenses . Its FDA-approved PE liners (chemically resistant to mineral and synthetic base oils) ensure compatibility with a wide range of lubricants, while the lightweight design (35kg empty weight) lowers shipping costs by reducing fuel consumption during transport .

Collapsible Design: When empty, the IBC collapses to 20% of its full volume, reducing storage space by 80% compared to rigid IBCs and lowering warehouse costs. This design also eliminates return shipping expenses associated with reusable steel containers .

Chemical Resistance: The inner PE liner (140μm thickness) is formulated to resist swelling and degradation from base oils, withstanding 6 months of continuous contact without leakage or material breakdown. It is compatible with Group I, II, III, and IV base oils, as well as common additives like viscosity index improvers .

Stackable Strength: Reinforced with vertical cardboard ribs, the IBC supports 5-ton static loads when stacked (up to 3 units high), making it suitable for efficient warehouse storage and transport in standard trucks (24 units per 20-foot container) .

Eco-Friendly: The outer cardboard shell is made from 80% post-consumer recycled materials and is fully curbside recyclable. The PE liner is incinerable with minimal toxic emissions, reducing the environmental impact by 40% compared to plastic IBCs .

Lubricant Production:

Delivers bulk base oils to manufacturers of motor oils, hydraulic fluids, and industrial greases, supporting continuous production lines with reliable bulk supply.

Supports bulk supply to automotive service centers, machinery maintenance facilities, and industrial plants requiring regular lubricant replenishment.

Metalworking:

Transports cutting fluids, coolants, and metalworking oils to machining shops and manufacturing facilities, where consistent oil quality ensures optimal tool performance and workpiece finish.

Construction:

Delivers asphalt binders, concrete admixtures, and construction lubricants to job sites, with the durable design withstands rough handling during offloading.

Q: Is it suitable for hazardous liquids?

A: No, it is certified for non-hazardous industrial liquids only. For hazardous materials, we recommend our specialized chemical-resistant IBCs with UN certification.

Q: What is the shelf life?

A: When stored in dry environments (relative humidity <60%) and temperatures between 5°C and 35°C, the IBC maintains integrity for up to 12 months from the production date.

Q: How is it disposed of?

A: The cardboard outer shell is curbside recyclable in most regions. The PE liner can be incinerated in industrial facilities or recycled through plastic recycling programs, with clear disposal instructions printed on the exterior for easy handling.

+86-(0)532 6609 8998

+86-(0)532 6609 8998